by Dr. Yves Ngabonziza (yngabonziza@lagcc.cuny.edu)

Teaching is one of the prestigious professions where one is involved in shaping the future of the country and the world. My drive towards helping my colleagues and participating in tutoring activities through my academic career as well as my experience as a student has slowly developed the “teacher and researcher” in me. I strongly believe that the best way to learn is to teach as I continue to learn through research and students ’contribution to various research projects. I also believe a good teacher not only educates students on available knowledge, but also helps them improve problem-solving abilities, develop information-seeking mindsets, and acquire life-long learning skills. As a student, research made a huge impact on my love for science and engineering and shaped who I became. That is why the use of research to enhance learning for students has been a subject of a number of reports from educators and researchers and have been shown to improve student participation. There is broad recognition that meaningful learning in engineering requires that students master fundamental concepts, rather than memorize facts and formulas [1]. Extensive literature demonstrates that traditional educational methods are frequently ineffective for addressing fundamental student misconceptions [2]. Studies have shown that student participation in research activities helps them visualize their academic careers, increases their productivity, and has an overall impact on their college success [3]. In addition, the use of inquiry-based activities effectively addresses misconceptions held by students [4].

My research interest has covered four areas: (a) Carbon Nanotubes, (b) Composite Materials Self-Sensing, (c) Engineering Education, and (d) Finite Element Analysis of Composites Materials.

Since the discovery of carbon nanotubes (CNTs) four decades ago, a considerable amount of research has been conducted on processing, properties, and applications of CNTs. Single-walled carbon nanotubes (SWCNTs) or multi-walled carbon nanotubes (MWCNTs) are single or multiple layers of cylinders rolled up from graphene sheets. It has been found experimentally and theoretically that carbon nanotubes can possess exceptional mechanical properties. In addition, CNTs display superior thermal and electrical properties, which, combined with their low density, make them an excellent candidate for composite reinforcement.

Currently, there are three main commonly used methods to introduce CNTs into polymers, i.e., solution processing, in situ polymerization of CNTs-Polymer monomer mixture and melt mixing of CNTs with polymers. In the context of industrial applications of polymer-CNTs systems, melt mixing is the preferred method of composite preparation. Here, an injection molding method which belongs to the melt mixing method was used to produce our CNT-Polymer nanocomposite specimens. The main challenge was the optimization of production parameters such as injection speed, temperature, and pressure, among others, to achieve homogeneous dispersion of CNTs in target polymer base. During my graduate studies, I focused on a comprehensive analysis of electrical and mechanical properties of carbon nanotube (CNT)-polymer composites produced by injection molding.

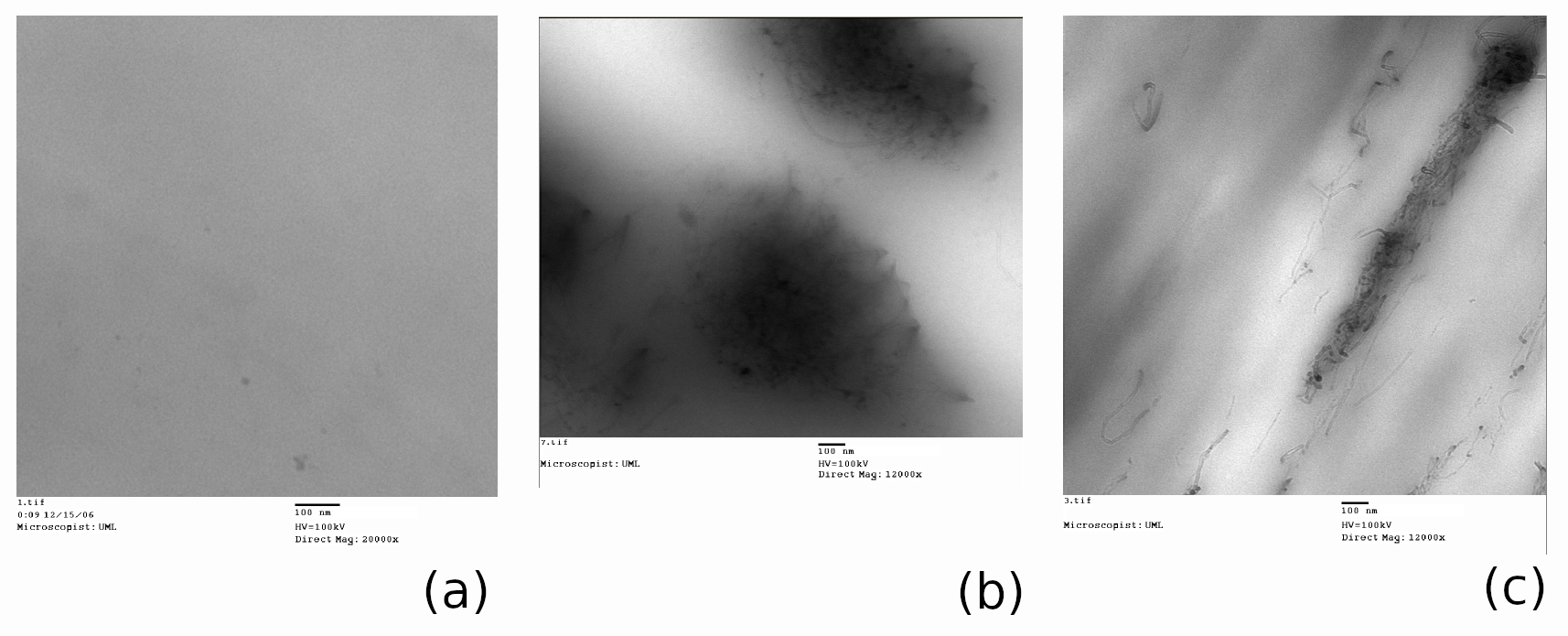

My dissertation research included four parts: (a) Fabrication of CNT-Polymer composites. We noticed that the injection velocity has an influence on the orientation of CNT. They align themselves from random bundles (at low injection speed) to aligned fibers (at high injection speed) within the composite material.

Figure 1: Injection molding machine used to produce specimen.

Figure 2: TEM images for (a) virgin Polypropylene (PP) material, and 2weight % CNT-PP composites at injection rate of (b) 1in/s, and (c) 7in/s.

(b) Electrical conductivity of CNT-Polymer composites. The knowledge about the percolation value for the CNT-Polymer composites conductivity helps to determine when these composites change from insulators to conductors. This would help with the industrial applications of CNT-Polymer composites. In order to model the relative resistance change \(\Delta R/R_0\) and CNT-Polymer composite conductivity as a function of material loading condition, the equation below was used:

\begin{equation}\tag{1} \frac{\Delta R}{R_0} = \frac{1+\epsilon}{\sigma/\sigma_0}-1, \end{equation}where \(\epsilon\) is the tensile strain, \(\sigma\) is the conductivity and \(\sigma_0\) the initial conductivity without loading.

In addition, we revealed the effect of injection speed on electrical conductivity; (c) Experimental investigation of mechanical behavior of CNT-Polymer composites, and (d) Micromechanics modeling of CNT-Polymer composites. The elastic modulus of the CNT-Polymer composites was studied and showed a dramatic increase by less than 10weight% of CNT. The existing theoretical models predicted well compared to our experimental results. The results showed the importance of the interphase properties on the overall elastic properties of CNT composites. In addition, strain-rate sensitivity was observed for the CNT-Polymer composites. Viscoelastic behavior of the CNT-Polymer composites was studied as well.

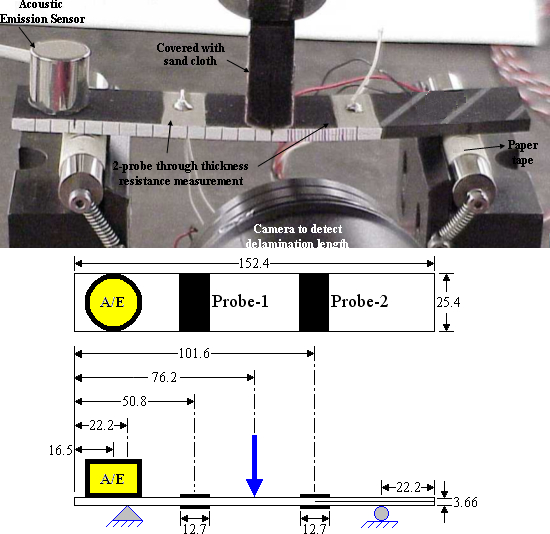

Furthermore, I have also worked on self-sensing of damage in carbon fiber reinforced structures and systems. Carbon fiber composites are basically piezoresistive and electrically conductive. Thus, the material characteristics provide damage and strain self-sensing capabilities. Self-sensing means that the material itself functions as a sensor and, thereby, eliminates cumbersome third-party sensor embedding, which presents technical barriers to the aircraft manufacturers as well as economic burden to airlines. In self-sensing, electrical contacts (electrodes) play an extremely important role in electrical resistance signal acquisition form flight critical composite aircraft structures. Hence, electrodes must be functionally effective, durable, and protected from flight environmental hazards. The use of change in electrical resistance for monitoring fracture process has been used in a set of tests we conducted to validate the effectiveness of the technique. Both static and fatigue tests on Double Cantilever Beam (DCB) and End Notch Flexure (ENF) specimens were conducted and the self-sensing technique showed effectiveness vis-à-vis crack detection capability. The figure below shows the experimental set-up of an ENF specimen for fracture detection.

Figure 3: A carbon-fiber composite laminated ENF specimen is mounted in an MTS universal testing system through a three-point bending fixture (also shown with surface-mounted two-point probe self-sensing electrodes, optical side markers, and A/E sensors).

Since joining LaGuardia, my research interest has expanded to engineering education, and finite element analysis of composite materials. This expansion was fueled by the drive to make research accessible to two-year school students combined with limited advanced laboratories availability. Research with LaGuardia students has resulted in students’ publications, presentations at different conferences and symposiums, and has reinforced students’ scholarship and transfer applications. Finally, I would like to highlight some research topics that LaGuardia students I mentored have worked on: (1) The effect of the temperature change on a cantilever composite beam material subjected to mechanical loading using Solidworks, (2) Mesh Effect on Computer Simulation of a Loaded Simply Supported Composite Beam to compare simulation results to theoretical calculations and analyze how meshing affects the accuracy of simulation results, (3) A Parametric Study on Geometry, Materials, and Testing Methodology to assess the tensile strength of 3D-Printed composite specimens comparing experimental and simulation results, and (4) The Effect of 3-D Printing Parameters on Specimen Tensile Strength.

[1] A. Lightman and P. M. Sadler, “Teacher predictions versus actual student gains,” The Physics Teacher, 31: 162–167, (1993).

[2] R. A. Streveler, T. A. Litzinger, R. L. Miller, and P. S. Steif, “Learning conceptual knowledge in the engineering sciences: Overview and future research directions,” Journal of Engineering Education, 97(3): 279–294, (2008).

[3] S. R. Gregerman, “Improving the Academic Success of Diverse Students Through Undergraduate Research,” Council on Undergraduate Research Quarterly, December 1999.

[4] M. J. Prince, M. A. S. Vigeant, and K. Nottis, “A preliminary study on the effectiveness of inquiry-based activities for addressing misconceptions of undergraduate engineering students,” Education for Chemical Engineers, 4(2): 29-41, (2009).